Your offsite SIPs and timber frame subcontractor

Working with KTS, contractors will access our decades of construction experience across our knowledgeable team members. Each project benefits from our comprehensive estimating and detailing, plus contracts manager and STA approved erectors on-site. Our CAD engineered SIPs and timber-frame wall panels benefit from our certified, integrated management process at our Bedfordshire factory.

More than just a build system sub-contractor

While our offsite build systems benefit from CAD manufacturing and pre-fitted insulation that helps you achieve your required u-values, working with KTS offers more than just an energy-efficient building envelope. Working with KTS as your superstructure sub-contractor gives you access to the following benefits

-

We only work with STA Approved erectors who must have SSIP accreditation

-

On-site mechanical handling and fall prevention systems included in quotation as standard

-

Offsite Fire Risk Assessment (OSFRA) and any necessary mitigation products

-

U-values, condensation risk and thermal bridging calculations prepared by our technical team

-

An extensive suite of fire resistance test reports from accredited laboratories confirming the performance of our systems

-

Architects Guide - a comprehensive set of typical details for our build systems, which illustrate the interaction of our frame with other elements of the build

-

Superstructure engineering for the frame, including early preparation of line and point load information to enable foundation design to commence

-

Appointed contracts manager conducting site visits and coordinating our delivery and erection schedule works within your project timeframe

-

A designated design coordinator ensures your build achieves optimal results within your budget and project parameters

-

We offer access to our team's extensive technical expertise and structural input, ensuring all your questions are addressed

-

We provide solutions that are compliant with relevant building regulations and your specific project requirements

-

Our team will manage the structural calculations for your project, ensuring a stable and safe build

-

We provide construction guidance, supporting you with superstructure-related advice throughout the project

Previous partners

We've worked with a number of contractors on construction projects across the UK. Here's just some of our previous partners.

Industry accreditations

KTS is backed by industry accreditations

ISO certifications

A foundation for quality and trust. Our construction accreditations signify our professionalism within the industry. They demonstrate that we are committed to adhering to regulations and meeting specific legal requirements.

Offsite construction for an efficient build

Offsite construction for housing developments and commercial construction has a number of benefits:

- Build accuracy. Ensures components are built to exact specifications in a controlled factory environment

- Less on-site disruption. Each component of the panel is constructed and assembled offsite, from the external breathable membrane to the internal timber service battens.

- Reduced on-site labour. With a large proportion of the build manufactured offsite compared to traditional methods of construction

- Less waste. Prefabrication minimises on-site cutting and construction reducing waste and disposal costs.

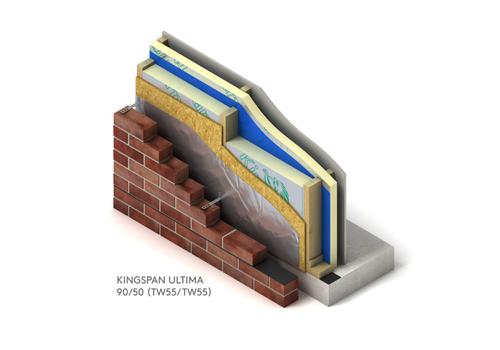

Our build systems

Get a head start in the early stages of your project with our expertise. You'll be able to leverage our knowledge across a wide range of scheme types and sizes to help make early informed decisions.

Proven product performance

Why I worked with Kingspan Timber Solutions

Kingspan Timber Solutions provided the timber frame system, Kingspan ULTIMA for 3 homes I built in Northamptonshire, they made the whole process simple from start to finish.

Roger Bettley, Developer